Flexography

Flexographic printing, or flexography, is a particular printing technique widely used in marketing to create high-quality packaging.

How does it work?

This is a rotary printing process in which the ink is applied to the substrate to be printed using flexible polymer matrix plates, called clichés in typographic jargon. The inking is applied by a steel or ceramic roller (Anilox roller) that is loaded with ink using two different systems: the first, using an inkwell filled with liquid ink, while a blade (squeegee) removes the excess from the surface of the roller; the second system uses a rubber roller that, in addition to drawing the ink from a basin and transferring it, also acts as a spatula. Drying is part of the printing process and can be done in two ways: infrared for solvent-based inks to be polymerized, or hot air for water-based inks, which are safer and more sustainable and suitable for food packaging. Finally, the substrate is extracted from the machine, cut and assembled.

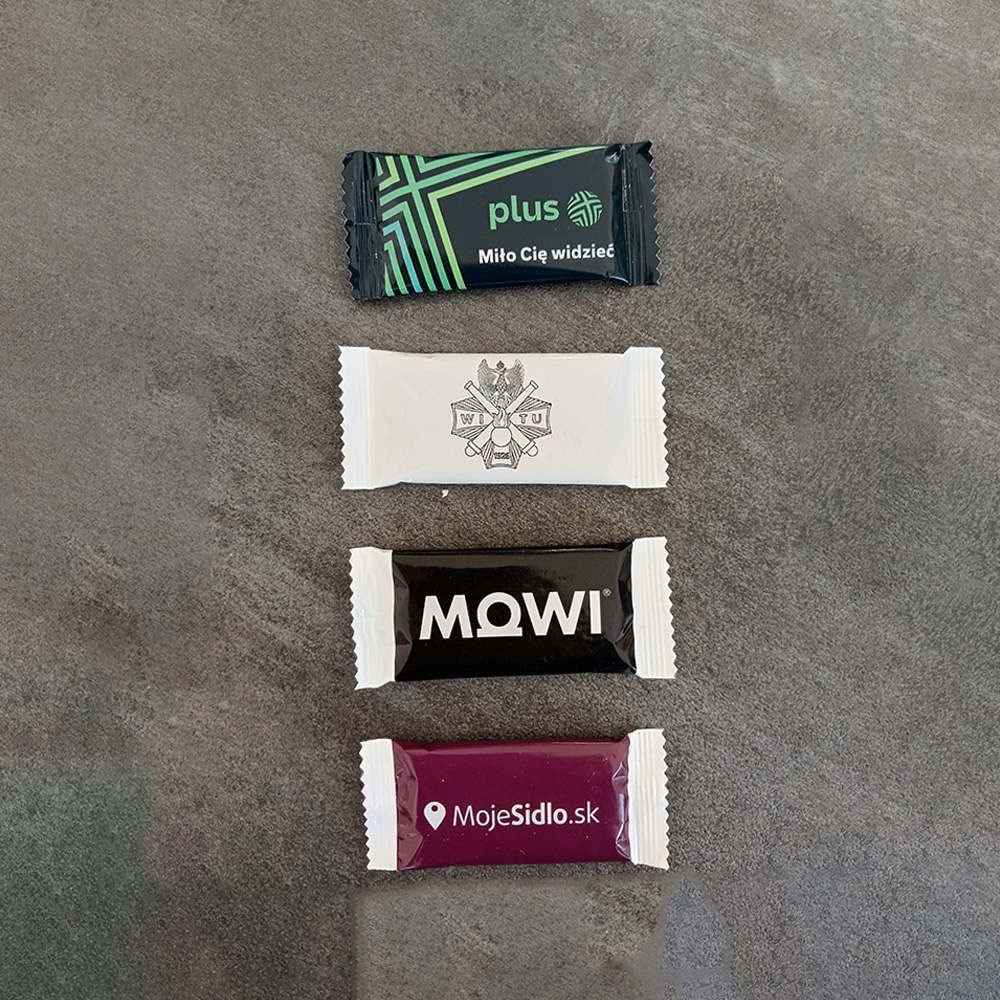

Some examples of application on promotional items

Flexography is used for food, pharmaceutical and cosmetic packaging design. On HiGift you can find it for candy and chocolate packaging.

Pros and Cons of Flexography

Pros

- Even very complex graphics can be reproduced over the entire surface;

- High quality full color printing, no limits on the use of colors;

- Ensures speed, precision and accuracy;

- It is versatile because it can be printed on a wide variety of materials and supports.

Cons

- It can only be used with very high minimum orders.