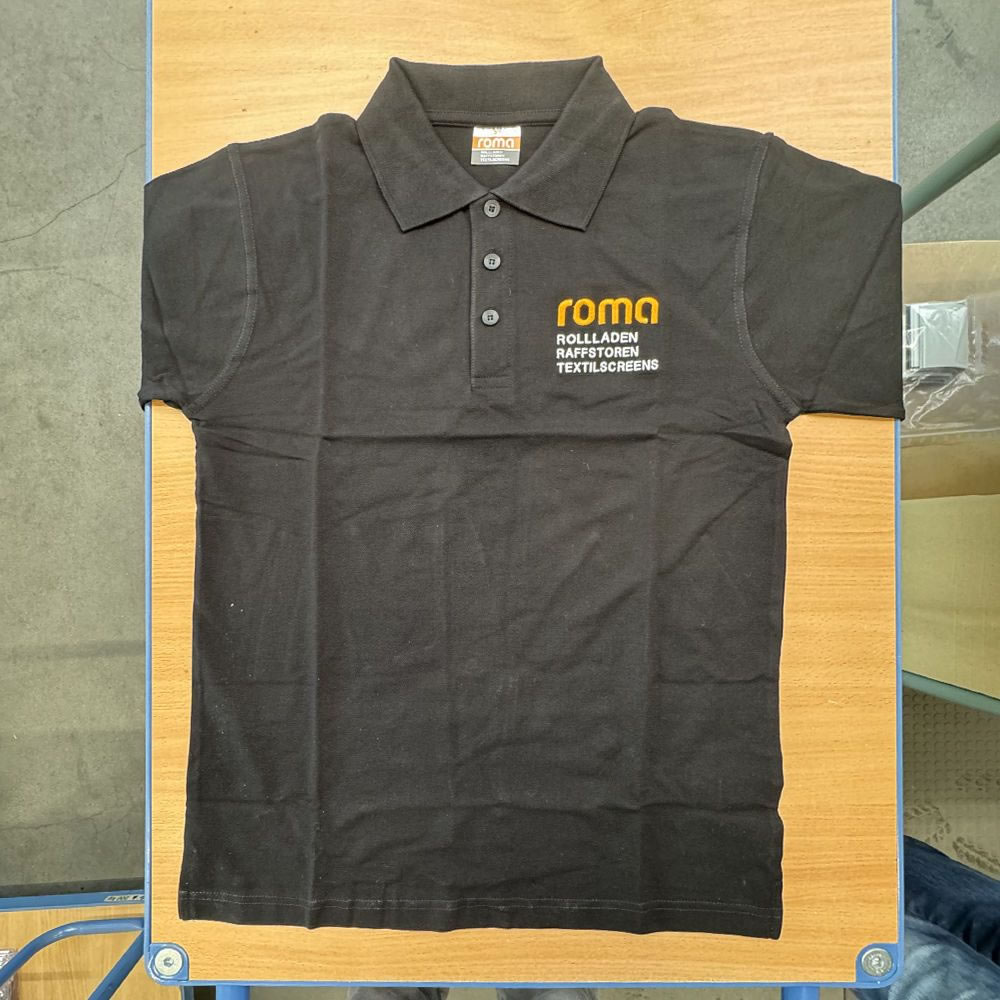

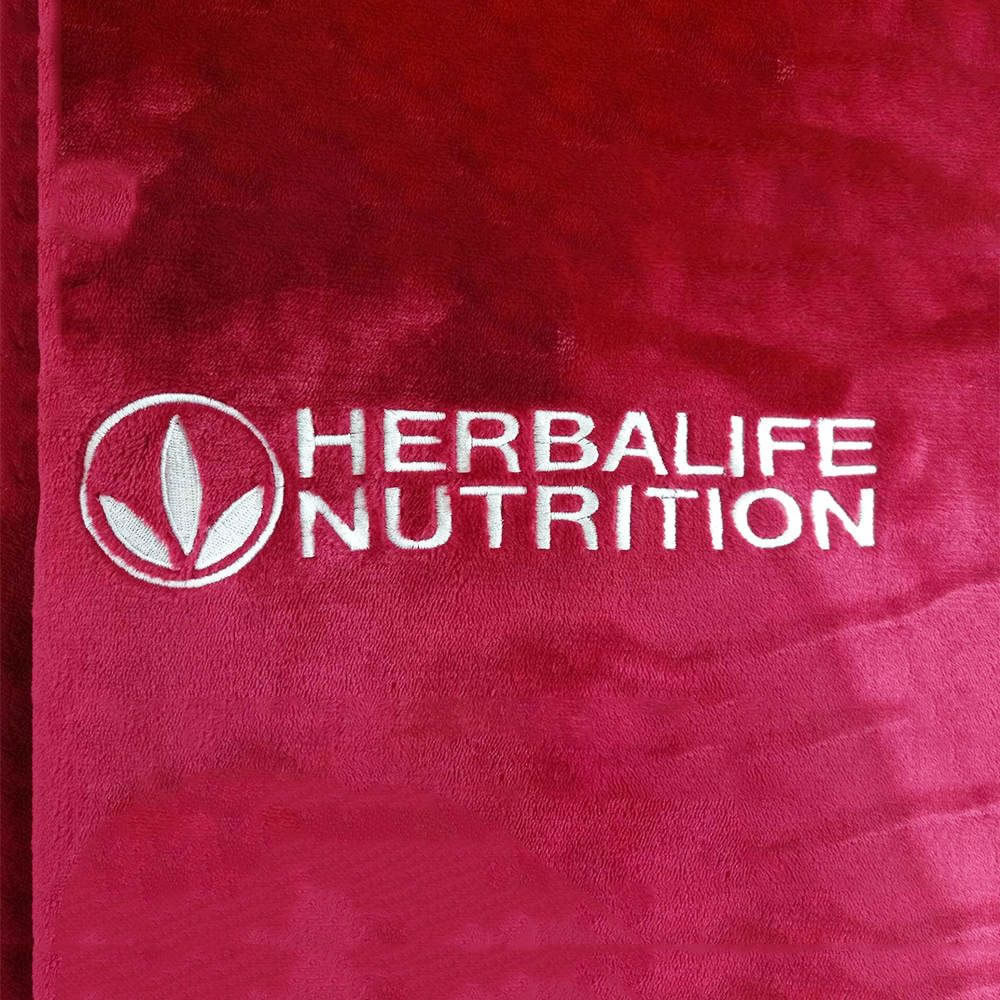

Embroidery

Embroidery is a customisation technique that involves applying the logo directly to the fabric by means of a needle and thread. Today the procedure is carried out by automatic embroidery machines thanks to which a precise and clear, durable and wash-resistant yield is obtained.

How does it work?

The graphics to be embroidered are transmitted to a special software that transforms them into a file containing all the information useful to the embroidery machine such as the number of colours, the size, the type and direction of the stitch, and other specific parameters. The sewing area of the product is then inserted into a frame so that the fabric remains flat and taut. A special sheet of paper is placed above and below the printing area and serves as a support.

What can I embroider?

Embroidery is a versatile technique because it allows you to customise many promotional items such as clothing and accessories, shoppers, hats, aprons and towels. Embroiderable fabrics, such as cotton, polyester and microfibre, must have a certain weight to ensure that they do not break during processing and that a high quality result is guaranteed. You can embroider simple logos, not too detailed up to a maximum of 12 colours. It is not possible to obtain the perfect pantone colour match, due to the limited colour availability of the wires. In addition, it is not possible to reproduce shades but only flat colors.

Pros and Cons

Pros

- It is durable and resistant to wear and washing;

- It is precise;

- It gives the graphics three-dimensionality;

- Does not require additional materials such as inks or plastics;

- It gives a sense of elegance and professionalism.

Cons

- It is not possible to reproduce very subtle nuances or details;

- Logos can be reproduced up to a maximum of 12 colours;

- Too detailed logos cannot be embroidered.