Relief

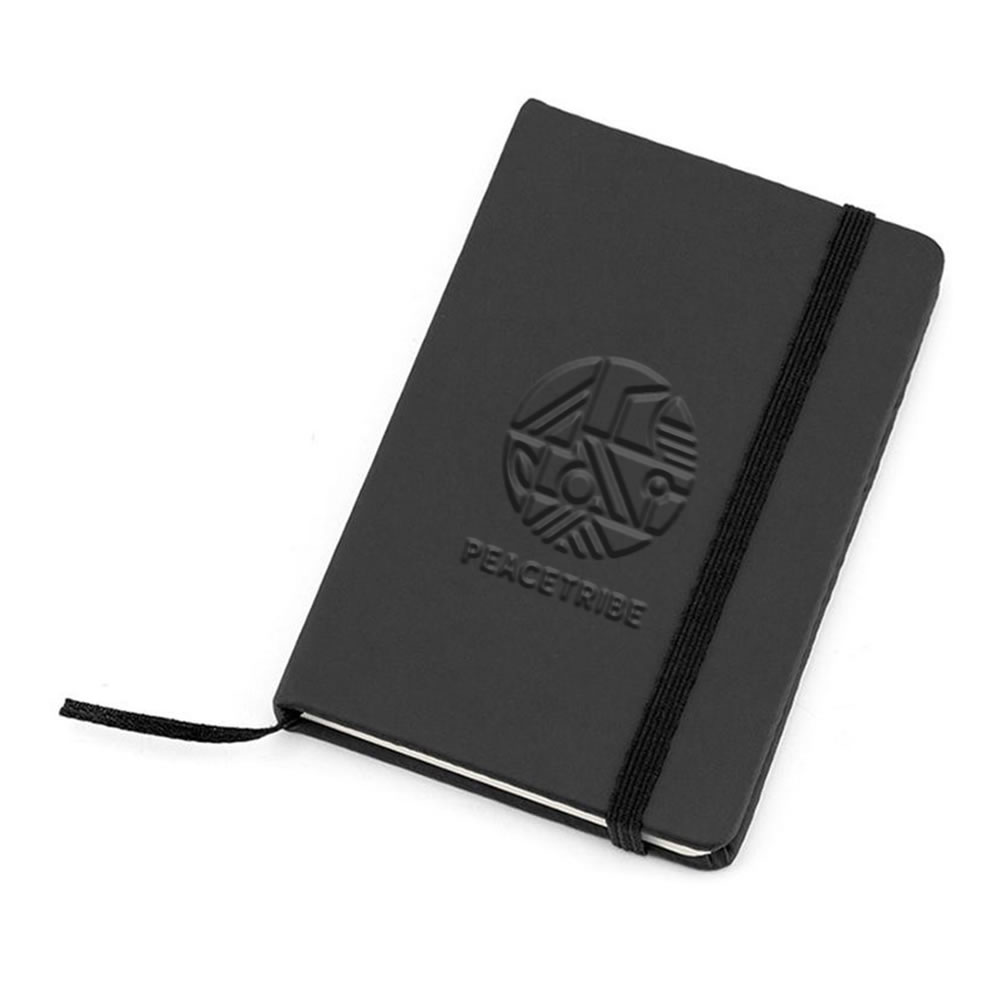

The raised relief also known as embossing is a technique that allows to permanently deform a surface to obtain an elegant and deluxe result. You can perceive to the sight and touch that the logo or writing is raised compared to the base of the product.

How does it work?

The metal matrix of the negative logo is created. The article is then pressed between the two parts of the matrix, generating the relief.

Some examples of application on items

Embossing is applied on paper, silicone, leather or imitation leather products.

Pros and Cons of Embossing

Pros

- A finish of this type ennobles the product and attracts the attention of the consumer;

- It is durable and permanent.

Cons

- The color cannot be reproduced;

- Too detailed logos cannot be reproduced;

- Not suitable for very thin materials.